A 17-year-old inventor might have just helped pull down the cost barrier for cost-conscious consumers of electric vehicles. While electric cars have become more affordable over the past few years, the rare raw materials needed to construct the motors have led to inflated car costs. Some new groundbreaking research may change the tide and lead to less expensive electric cars in the future.

A chance video viewing led to unexpected innovation

A couple of years ago, 17-year-old Florida-based inventor Robert Sansone viewed a video about the pros and cons of electric cars and saw that the substances needed for motor production were made from rare materials, which can cost hundreds of dollars per kilogram.

Sansone’s past inventive endeavors and interest in motors inspired him to see if there is a more cost-effective way to power electric cars. The answer? A synchronous reluctance motor. Sansone came to find that these motors may subtract the need for rare metals because of a novel design approach.

Why Sansone’s discovery may be the answer

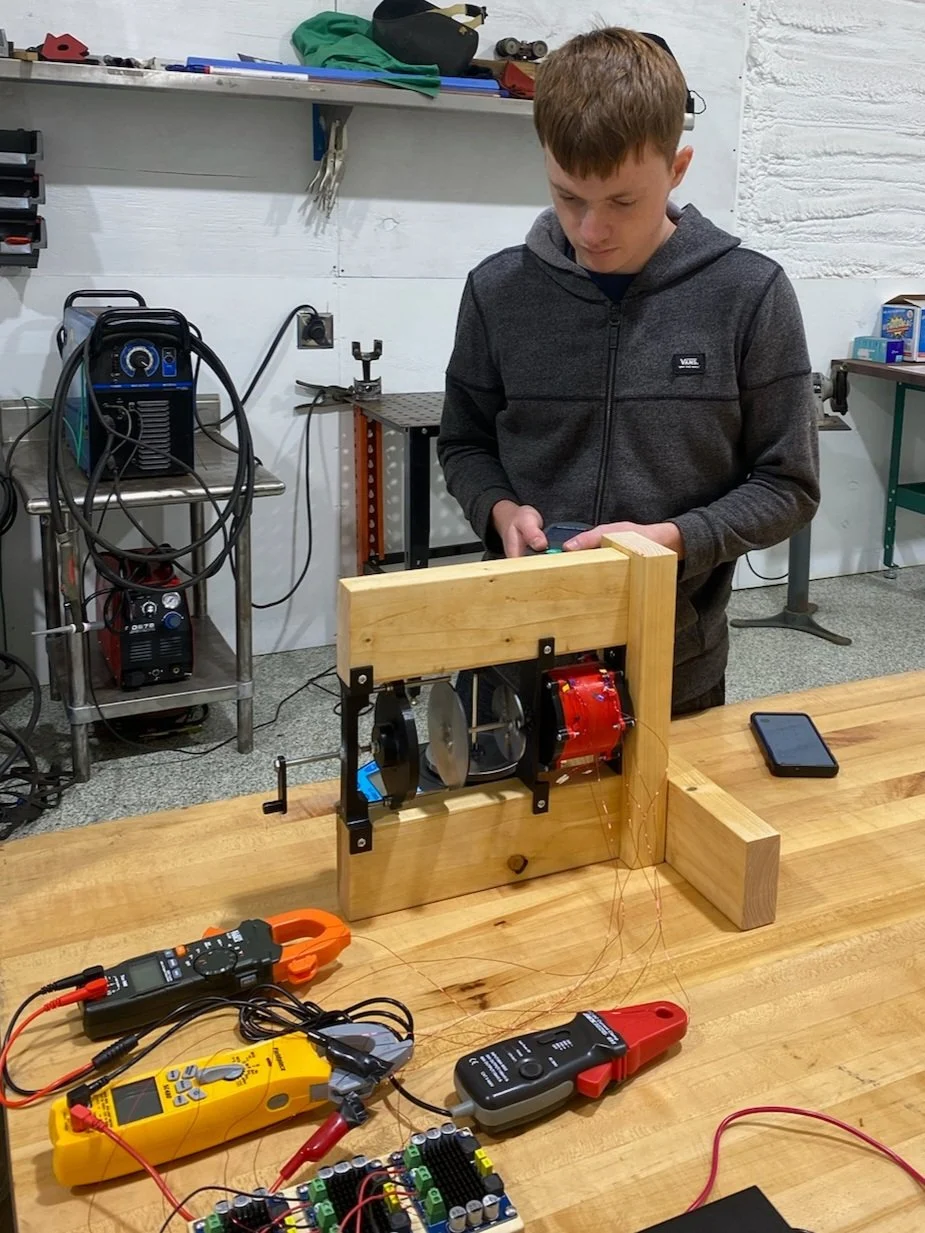

It’s challenging to remove precious metals from motors, so Sansone’s intricate testing process is a gamechanger. Over one year, Sansone worked on a dedicated prototype made of 3-D printed plastic, copper wires, and a steel rotor.

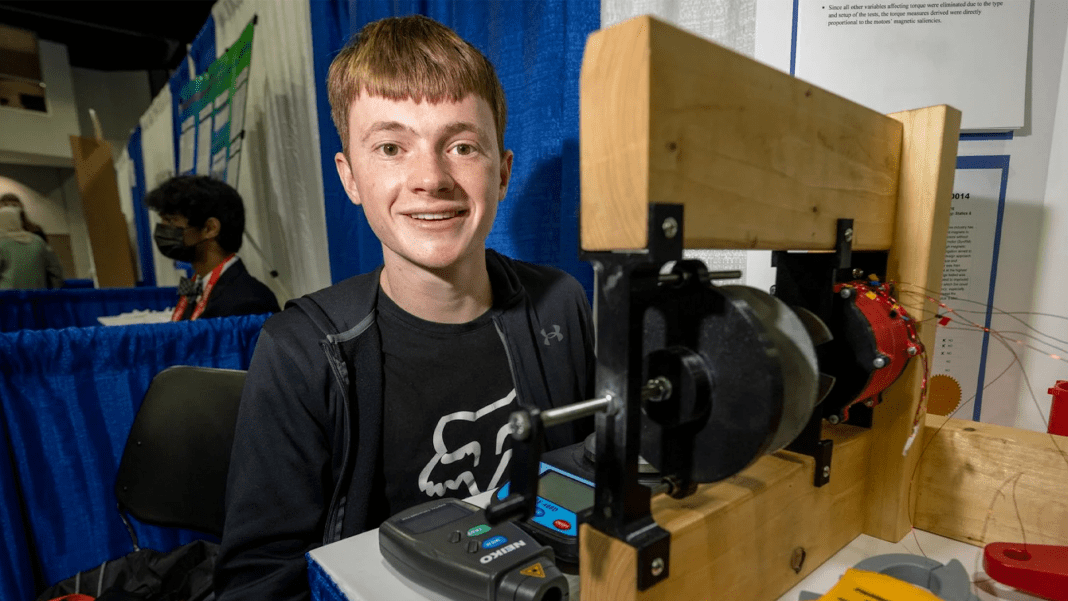

His efforts were so well-received that he was awarded $75,000 and came in first place at the Regeneron International Science and Engineering Fair, an international STEM fair and competition for high school students. After one year, Sansone’s work resulted in him creating a working prototype of a synchronous reluctance motor that could power an electric car.

What differentiates the synchronous reluctance motor?

The synchronous reluctance motors don’t use magnets and are typically used in small appliances like fans. Sansone decided to put his prototyping efforts toward creating a synchronous reluctance motor that could power an electric vehicle motor. A typical motor has a steel rotor that has air gaps. Sansone did away with the air gaps by using a second magnetic field to produce more torque — or rotational force.

The excellent nature of his design is that his work increases the saliency ratio — the difference between the magnetism and materials, increasing the torque. There is a lot more to Sansone’s design, but the details have been kept secret until Sansone patents the technology.

The far-reaching impact

Sansone’s work could have a major impact on electric vehicles — particularly their composition and resulting cost. However, there are still some issues with Sansone’s design. According to Heath Hofmann, a professor of electrical and computer engineering at the University of Michigan, the materials needed for this type of motor are affordable. Still, manufacturing could be more involved, resulting in higher production costs. This increase in manufacturing cost could be a barrier to this type of motor being mass-produced.

Yet, there could be a workaround, especially if 3D printing plays a more prominent role in manufacturing. In a “Smithsonian Magazine” article, Sansone agreed with the fact that there are obstacles to using this type of design, but he also added:

“With new technologies like additive manufacturing [such as 3-D printing], it would be easier to construct it in the future.”

Before changing how electric vehicles are powered, we may still have a way to go. Nevertheless, Sansone has started the conversation and began a move toward looking at more cost-effective and sustainable ways to power electric vehicles and make them less expensive for potential customers

Did you enjoy this article? Please share your thoughts, comments, or questions regarding this topic by connecting with us at newsroom@cbtnews.com.

Did you enjoy this article? Please share your thoughts, comments, or questions regarding this topic by connecting with us at newsroom@cbtnews.com.

Be sure to follow us on Facebook, LinkedIn, and TikTok to stay up to date.

While you’re here, don’t forget to subscribe to our email newsletter for all the latest auto industry news from CBT News.